How To Repair A Rusted Tulip Panel

How To Brand A Patch Panel

Article past Mark Trotta

If a body panel has rust spots but no standoff damage, replacing the whole panel may not be necessary. An alternative is to cut out merely the rusted area, then brand a template, trace it onto canvass metal, cutting it out, and weld it in. This is a time consuming process, but having the right tools will save you time (providing that y'all use them correctly).

What A Body Shop Will Practise

If you bring your motorcar to a body store, they'll want to replace the entire panel, regardless of whether or non it tin be repaired. This is elementary economic science - it'south quicker and more cost-effective for them to replace the whole panel. The labor may be less, but overall yous'll pay more once y'all include the cost of the replacement panel. This often puts the repair out of a person's restoration budget.

Provided you are a decent welder, you tin can salve coin by cutting out the bad metallic, making a patch panel, and welding it in. If you're just getting started with automotive body repair, a MIG Welding Machine is a proficient choice. They're easiest welding procedure to learn and they're also cheapest to buy. Near people tin can produce quality, practiced looking welds with minimal practice.

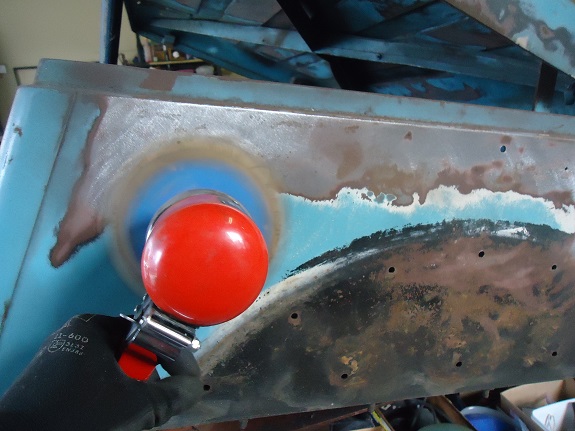

Yous need to bring the panel downwards to blank metallic. A D/A sander works best for this. An angle grinder with a wire brush zipper can also be used.

Earlier cut out the rusted metal, take a wire brush and/or scraper and remove any loose rust on the trunk panel to be worked on. Then take masking tape and marking out nigh one inch beyond the rusted-through part. You want to remove as little adept metal as possible.

Cutting and Removing Rusty Panels

Cut out damaged metallic can be done several ways. An air compressor and cutting-off bike is one popular method. Another way is with an electric angle grinder.

In one case the bad metal is cut away, an air sander can be used to bring the area down to bare metal.

Sand across the rusted area an inch or then. A 36-grit sanding disc works the fastest. Clean the exposed metal area with a 60 or lxxx-dust disc. You should now have a shiny, solid rust-free surface.

Patch Panel Template

After advisedly cutting out all the rusted metal from the console, the next step is to brand a patch template. Take measurements and transfer them to a piece of cardboard (the kind yous tin can cut with a scissor). Depict and cutting a template of the patch console needed.

Start larger than you need. Scribe or mark the cardboard template onto a piece the piece of sheet metal. You can use a black mark to mark the cut, remembering to add together near an 1/eighth" or so to the line for trimming.

It'southward easy to remove metal - much more than difficult to add it!

Cutting Canvas Metallic

Canvas metal tin can be cut in a number of ways. Hand-held nibblers and can-snips work fine for smaller patches, merely electric shears will save time on larger patches. Once you have the crude patch cutting out, carefully trim it down with manus-held snips.

Read: 9 Ways To Cutting Canvas Metal

Cease and check against the car for an exact fit. It's like shooting fish in a barrel to remove metallic - much more difficult to add it! You want to end up with a gap of no more than 1/eight".

Welding new to old rusty metal is always tricky, especially after grinding the rust off one-time sections, which thins the metallic even more. Burning through the old metal is always a worry.

All-time Metal For Patch Panel

You lot can buy a new piece of sheet metal stock, or utilise an old slice of panel from a donor car, equally long as it's grinded make clean and the same thickness.

How To Mensurate Sheet Metal Thickness

Yous tin measure sheet metallic thickness with a digital caliper or a sheet metal thickness gauge. Notation: Most classic American car torso panels are 20 or 22 approximate. On pre-1970's cars, the width of the original sheet metal is often thicker (18 or xx guess).

Curved Patch Panels

Patching into a curved area of the car trunk volition take more time and skill than a simple flat patch. Before cutting out the old metal, study the damaged surface area and call back through the repair procedure.

You may make up one's mind to remove the entire section to make the patch and welding more attainable. Cutting the panel bigger than the damaged area may give you a cleaner and easier butt weld.

Related Articles

MIG Welding Canvas Metal

All-time Welder For Automotive Restoration

Best Air Tools For Automotive Restoration

MIG Welding Helmet Review

How To Repair A Rusted Tulip Panel,

Source: https://www.restore-an-old-car.com/how-to-make-a-patch-panel.html

Posted by: lindnermung1940.blogspot.com

0 Response to "How To Repair A Rusted Tulip Panel"

Post a Comment